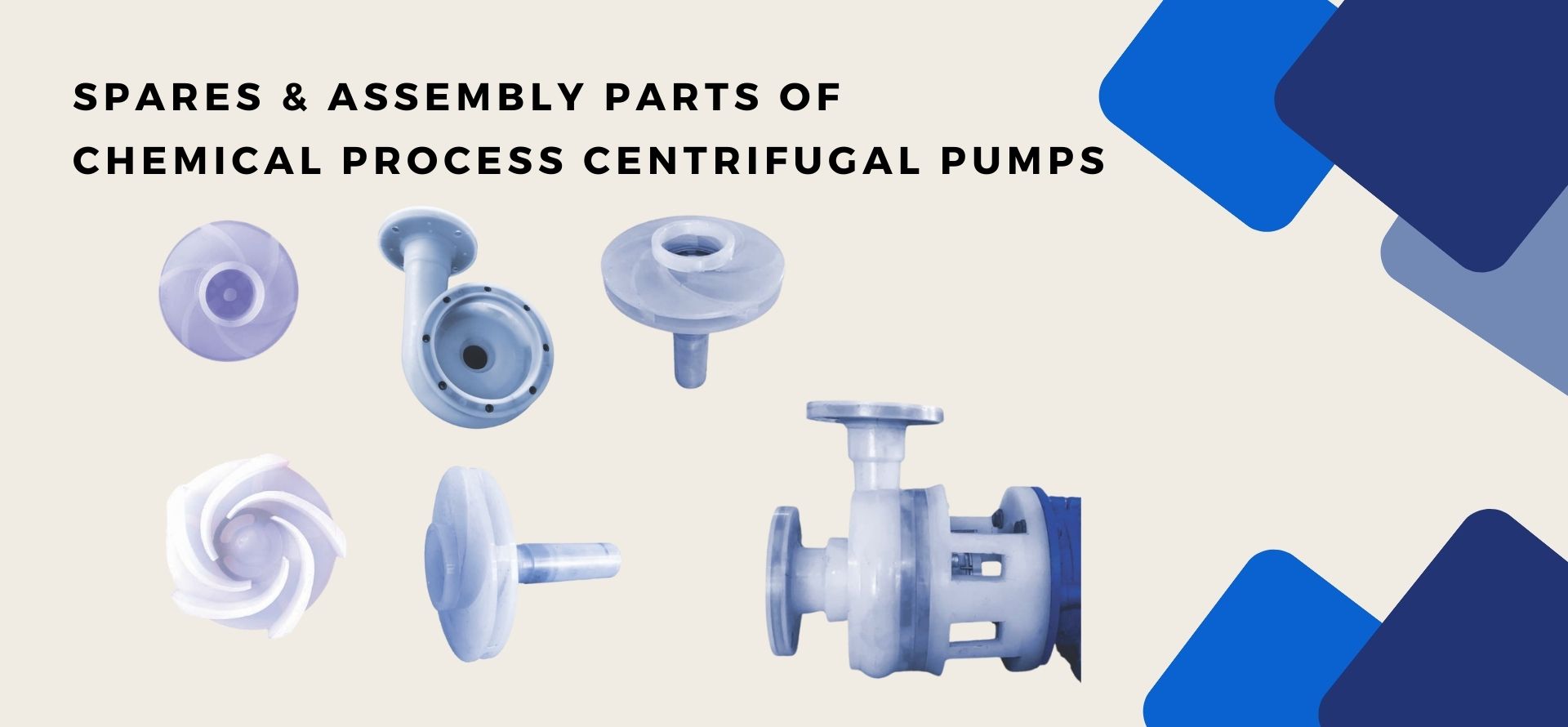

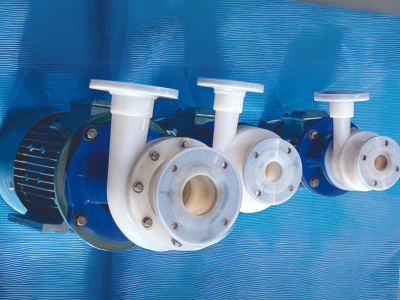

A pump casing, often regarded as the heart of a fluid handling system, plays a crucial role in ensuring the efficiency and reliability of pumping.

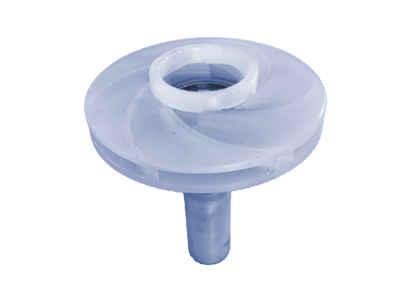

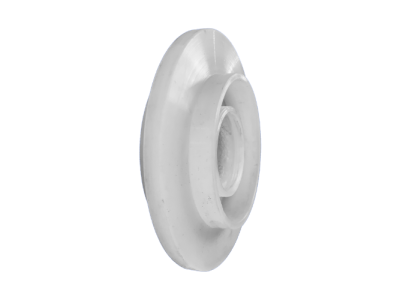

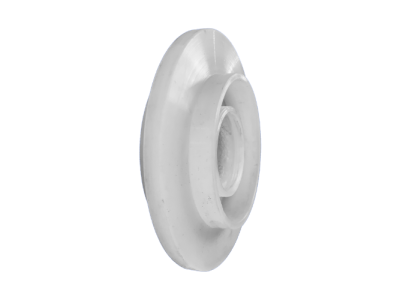

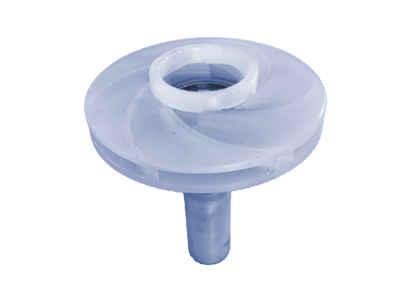

An impeller, whether closed or semi-open, is a vital component in various mechanical systems, particularly within the realm of fluid dynamics.

Explore our diverse range of other top-quality products, designed to meet your unique needs and exceed your expectations.

Where exceptional performance meets unmatched versatility, providing non-stick, chemical-resistant solutions for diverse applications.

Seamlessly combining the resilience of PTFE with versatile industrial solutions, ensuring corrosion-resistant and high-performance applications.

A pump casing, often regarded as the heart of a fluid handling system, plays a crucial role in ensuring the efficiency and reliability of pumping.

Explore our diverse range of other top-quality products, designed to meet your unique needs and exceed your expectations.

Where exceptional performance meets unmatched versatility, providing non-stick, chemical-resistant solutions for diverse applications.

Seamlessly combining the resilience of PTFE with versatile industrial solutions, ensuring corrosion-resistant and high-performance applications.

An impeller, whether closed or semi-open, is a vital component in various mechanical systems, particularly within the realm of fluid dynamics.

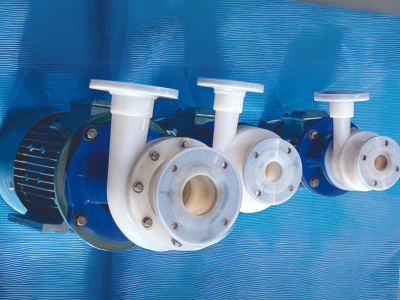

Paraflon Engineering Company was established in the year 2003, with the aim of manufacturing Non Metallic Centrifugal Pumps with closed and open impellers. The company today, is the first manufacturer of PFA/ FEP/PVDF molded complete non-metallic chemical process pumps in India. We also manufacture various highly corrosive chemical resistant lined/molded parts and products.

Our company has passed the ISO 9001:2015 international quality system certification. Our Products are widely used in chemical, pharmaceutical, environmental protection, metallurgy, paper, electronics, steel and other fields.

Our products resist highly corrosive chemicals at higher temperature products such as acids, alkalis, solvents and other corrosive liquids used in the Chemical Process, Petrochemical process, Refinery, Oil extraction, Bulk Drug Manufacturing, Power Generation, Food Processing, Effluent Treatment, Steel plants and similar core Industrial uses of Non- Metallic centrifugal pumps worldwide.

With over 20 years of experience, we bring a wealth of knowledge and proven solutions to the table.

Our products are at the forefront of technology, ensuring that you have access to cutting-edge solutions.

We pride ourselves on delivering products of the highest quality, engineered to stand up to the most demanding applications.

We are dedicated to excellence in every aspect of our business, from product development to customer service.

Chemically aggressive, even contaminated, media throughout the whole range of chemical processing technology, surface coating technology, environ-mental engineering and other areas of industry. The pump can be used in transporting strong corrosive medium of any concentration, such as sulfuric acid, hydrochloric acid, nitric acid, acetic acid, aqua regia, strong alkali, strong oxidants and organic solvents, etc. It is one of the most advanced corrosion-resistant equipment.

PARAFLON’s PFA/FEP/PVDF (Teflon) non-metallic centrifugal pumps and associated products have a wide range of application areas